Bishop State’s first-ever Wildcat Contraption Camp was designed to expose male and female students, ages 12 – 15, to modern manufacturing by creating, building, presenting, and taking a product home. At camp, students learned about manufacturing education paths at Bishop State, toured manufacturing facilities, learned about entrepreneurship, and met top industry experts.

Students were exposed to the various manufacturing career fields via in-person, hands-on classroom teaching. Some activities included using the virtual welding simulator to test their skills welding two things together. They built virtual roller coasters, drew housing blueprints, and created bridge replicas as they learned about architecture, blueprint drawings, and structural engineering.

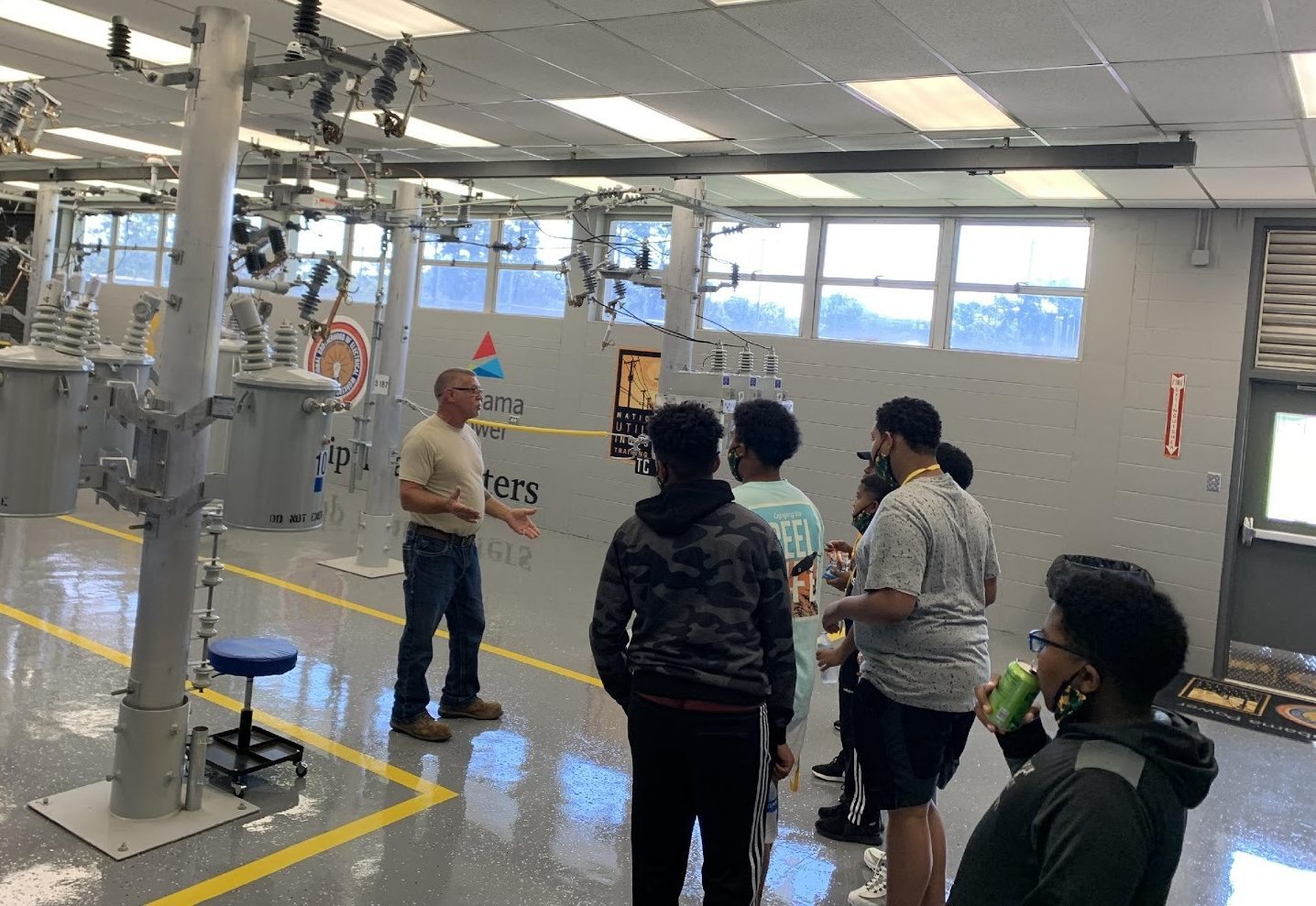

Campers visited the lineworker training facility on the Southwest campus and also learned about circuits from Alabama Power employees and how each one converts power across the city. They also experienced a simulator that showed them how to wire the boxes on the pole that the Alabama Power employees operate.

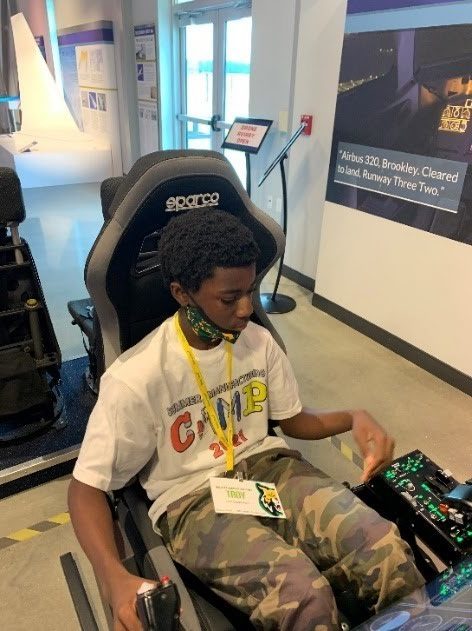

All of the learning did not take place inside a classroom or even one of Bishop State’s four campuses. Campers also got to get a first hand look at industries via facility tours. They went to Flight Works at Airbus where they learned about the history of Airbus and explored many exhibits that taught them about careers in the aerospace engineering career path. They were especially interested in the virtual reality experience and the cockpit simulator. They also toured the final assembly line - where commercial planes go when they are in final production. Amongst the many things they learned there, the one fact that stood out the most was the tires for the aircrafts cost $30,000 each!

Their final project was to build a custom remote controlled LED lamp. Campers were given supplies and followed a series of instructions to create the final project. The project taught students patience, teamwork, and the importance of following instructions.

All camp participants received a one-year student license for SolidWorks™ CAD software, a customized camp t-shirt, hands-on learning while creating take-home projects, and discovery that leads to the experience of a lifetime!

Bishop State was able to host this camp thanks to a $2500 grant from Nuts, Bolts & Thingamajigs Foundation.